Happy Valley is a

low‐lying urban area located in the hinterland of the Wan

Chai District and is surrounded by a hilly terrain.

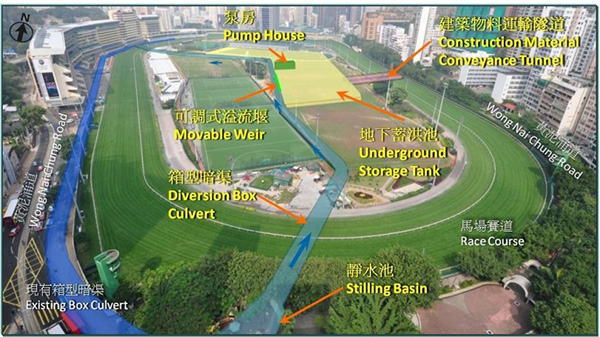

Serious flooding occurred in the Happy Valley catchment,

in particular the Happy Valley Recreation Ground (HVRG),

Hong Kong Jockey Club racecourse and nearby streets,

during heavy rainstorms in 2000, 2006 and 2008. To address

the flooding problem, Happy Valley Underground Stormwater

Storage Scheme (HVUSSS) at the HVRG is constructed. The

scheme would raise the flood protection level of the

drainage system in Happy Valley to cater for rainstorms

with a return period of 1 in 50 years, and in turn

significantly reduce the risk of flooding in Happy Valley

and areas in the vicinity.

The HVUSSS greatly enhanced

the flood protection level of the city and solved the

flooding problems in Happy Valley and Wan Chai districts.

The adoption of an innovative underground spillway energy

dissipation and flow conveyance design, a system of smart

and automatic movable weirs with real time control, water

harvesting system and green building designs have created

a more resilient and adaptable drainage system that blends

harmoniously with the environment. It has been awarded the

2018 Dai Yu Science & Technology Medal of Chinese

Hydraulic Engineering Society (“中國水利學會「大禹水利科學技術獎」”) for

the outstanding achievements of the HVUSSS in the area of

innovations and technology development.

In the early 2000s,

the Drainage Services Department proposed an

innovative “upstream interception” scheme, namely The

Hong Kong West Drainage Tunnel (HKWDT) to improve the

flood protection standard for areas around Causeway

Bay, Admiralty, Central and Sheung Wan.

The engineering challenge was

how to effectively intercept and transfer the

supercritical (high speed) flow from the steep natural

watercourses located in the densely‐populated

Mid‐Levels district to the drainage tunnel located

some 100 m below ground. The breakthrough was the

development of a compact bottom rack and vortex intake

system to stably decelerate the supercritical flow,

with efficient energy dissipation, for smooth

conveyance of flow from higher elevations to the deep

drainage tunnel and discharge to the sea.

Since commissioning of the

HKWDT in 2012, the vortex intake system has been put

to the test on many severe rainfall occasions, and

successfully protected the downhill urban areas of

Hong Kong Island from flooding. This system has set a

global standard for reference and the new vortex

intake design method has been adopted in many critical

hydraulic infrastructure designs internationally.

The supercritical vortex

intakes for the Hong Kong West Drainage Tunnel (HKWDT)

won the First Prize of Construction Sustainability in

Construction Innovation Award 2017 of the Hong Kong

Construction Industry Council (CIC).

Smart Urban Water

Supply Systems field testing facility, the first of

its kind in Hong Kong and Greater China, is

constructed at the Beacon Hill Intermediate Level

Freshwater Reservoir in Kowloon Tong, next to Lung

Cheung Road. The facility was designed and developed

by HKUST with the support of the Hong Kong Water

Supplies Department. This unique facility provides an

opportunity to test in‐pipe wave propagation with a

degree of realism not possible with laboratory

experiments without interference to the normal supply

of water to the public. A 250 m long pipeline network

of 150 mm HDPE pipe has been constructed along the

periphery of the site (covering a footprint of around

65 m x 65 m). The water supply is fed from the Beacon

Hill reservoir at around 60 m of head; the flow is

monitored by an electromagnetic flow meter, and the

upstream pressure can be set with a Pressure Reducing

Valve (PRV). A valve designed for rapid closure is

installed at the downstream end of the system.

Pressure transducers, branches and leaks can be

installed at selected nodes. The facility permits

field‐scale experiments on advanced, transient‐based,

diagnostic methods for leakage/fault detection and

pipeline wall condition assessment.